In the dazzling world of CNC machining, where robots meticulously carve intricate shapes from metal, it’s easy to overlook the human element. But the truth is, behind every flawlessly crafted part lies the expertise and dedication of skilled machinists – the true heroes of precision manufacturing.

At Precision Machining Excellence, we don’t just boast cutting-edge technology; we boast a team of seasoned professionals whose combined experience spans decades. These are more than just button-pushers; they’re problem solvers, artists, and engineers rolled into one, their hands and minds working in perfect harmony to bring your vision to life.

Experience that speaks volumes: Our machinists aren’t fresh out of training. They’ve honed their skills through years of working with diverse materials, tackling complex challenges, and mastering intricate techniques. Each member brings a unique perspective and expertise, ensuring we can handle any project with confidence.

Qualifications that matter: Don’t be fooled by empty promises. Our team is fully certified and trained in the latest CNC machining technologies and safety protocols. We invest heavily in their continuous education, ensuring they stay ahead of the curve and deliver the highest quality results.

Problem-solving that goes beyond the code: CNC machines are marvels of technology, but they’re not infallible. When unexpected challenges arise, it’s the machinist’s intuition and problem-solving skills that truly shine. They can decipher subtle nuances in the material, adjust parameters on the fly, and find ingenious solutions to ensure your parts meet your exact specifications.

Quality assurance built on dedication: Every part that leaves our facility undergoes rigorous inspections. But the real quality assurance happens on the shop floor, where our machinists take immense pride in their work. Their meticulous attention to detail and commitment to perfection are the cornerstones of our quality control process.

Customer satisfaction that’s personal: We believe in building relationships, not just processing orders. Our machinists are passionate about understanding your needs, communicating openly throughout the process, and ensuring you’re completely satisfied with the final product. They’re not just making parts; they’re building trust and exceeding expectations.

So, the next time you see a flawlessly machined component, remember the human element behind it. At Precision Machining Excellence, it’s the expertise, dedication, and passion of our machinists that truly elevate our services and deliver exceptional results.

Consider adding:

Short profiles of individual machinists, highlighting their experience and unique skills.

Quotes from machinists about their work and passion for the craft.

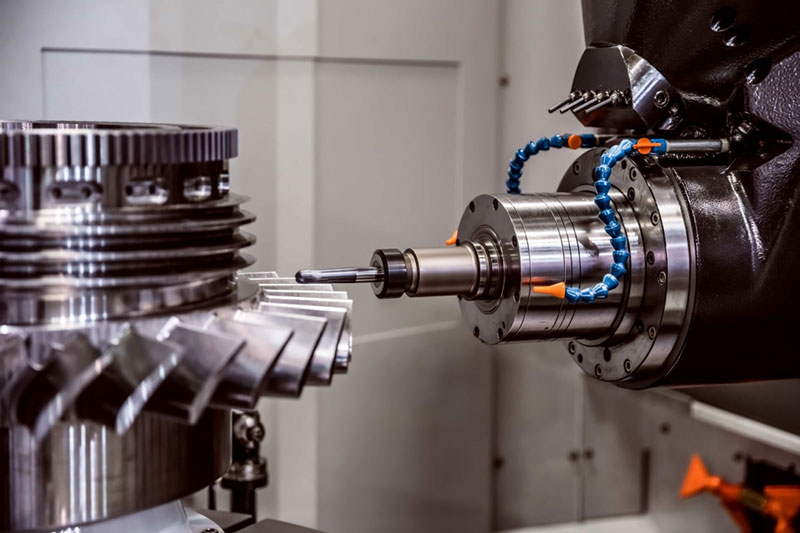

Images or videos showcasing your machinists in action.

A call to action inviting potential customers to learn more about your team and how they can contribute to their projects.

Key Takeaways:

Experienced and skilled machinists are crucial for high-quality results.

Precision Machining Excellence prioritizes team training and expertise.

Your company’s skilled workforce ensures reliable and customized solutions.